In industrial settings, managing heavy machinery plays a crucial role in ensuring smooth operations and maximising productivity. A well-defined Machinery Asset Management Strategy (MAMS) is essential for optimising the performance, reliability, and lifespan of machinery in a plant.

What is A Machinery Asset Management Strategy (MAMS)

A Machinery Asset Management Strategy (MAMS) encompasses a comprehensive set of systematic approaches, processes, and practices specifically designed to effectively handle the entire lifecycle of heavy machinery within a plant. It involves strategic planning, regular maintenance, proactive monitoring, and informed decision-making to ensure that machinery operates at its peak performance, achieves maximum uptime, and minimises operational risks.

At its core, MAMS aims to optimise the utilisation and efficiency of machinery by implementing proactive maintenance schedules, conducting routine inspections, and employing advanced monitoring technologies. By adhering to manufacturer guidelines and industry best practices, plant operators can extend the lifespan of machinery, reduce the frequency of breakdowns, and avoid costly downtime.

Furthermore, MAMS facilitates strategic planning to align machinery usage with production demands, enabling better resource allocation and minimising idle time. It also entails effective spare parts management, ensuring timely availability and reducing the risk of unexpected delays.

Another crucial aspect of MAMS is continuous monitoring and data-driven analysis. Real-time data collection using sensors and advanced analytics enables operators to detect anomalies, anticipate potential failures, and make informed decisions for preventive maintenance. This proactive approach helps identify underlying issues before they escalate into major breakdowns, thus maximising reliability and minimising unplanned downtime.

By implementing a robust MAMS, organisations can achieve several benefits, including improved equipment performance, increased reliability, extended machinery lifespan, reduced maintenance costs, and enhanced safety and compliance. Ultimately, a well-executed MAMS optimises overall operational efficiency and contributes to the long-term success of plant operations.

Benefits of Implementing Machinery Asset Management

Implementing a comprehensive Machinery Asset Management Strategy offers several advantages for plant operations.

Enhanced Equipment Performance

A well-executed Machinery Asset Management strategy or system ensures regular maintenance, calibration, and monitoring of machinery, optimising its performance and minimising downtime. By implementing preventive maintenance schedules, plant operators can proactively address potential issues, identify inefficiencies, and fine-tune machinery to operate at its peak performance.

This results in improved overall equipment effectiveness (OEE), increased production output, and better quality control.

Improved Reliability

By employing proactive maintenance practices, such as predictive maintenance and condition monitoring, potential breakdowns and failures can be detected early, reducing unplanned downtime.

MAMS allows for the implementation of advanced monitoring technologies like sensors and data analytics, which enable real-time data collection and analysis. This enables operators to detect anomalies, monitor equipment health, and address potential issues before they lead to catastrophic failures. Consequently, machinery reliability is improved, leading to increased uptime, reduced disruptions, and enhanced overall operational efficiency.

Extended Equipment Lifespan

Effective asset management practices, including routine inspections, timely repairs, and equipment replacements, can significantly extend the lifespan of heavy machinery, maximising return on investment.

A well-implemented Machinery Asset Management strategy ensures that equipment is properly maintained, lubricated, and calibrated, preventing premature wear and tear. By adhering to manufacturer guidelines and best practices, plant operators can avoid costly breakdowns, reduce the frequency of major repairs, and extend the operational life of machinery.

Cost Reduction

Optimised maintenance scheduling, spare parts management, and efficient resource allocation through MAMS can help reduce maintenance costs and minimise production losses due to equipment failures.

By establishing clear maintenance plans, operators can avoid unnecessary expenditures, optimise the use of spare parts, and minimise equipment downtime. Additionally, implementing cost-effective maintenance strategies, such as condition-based or reliability-centred maintenance, enables targeted interventions, reduces unnecessary maintenance activities, and maximises cost savings.

Enhanced Safety and Compliance

A well-maintained and properly functioning machinery fleet ensures a safer working environment for plant personnel. MAMS includes regular safety inspections, adherence to safety protocols, and compliance with regulatory standards.

By implementing safety measures, such as lockout/tagout procedures, routine inspections of safety features, and comprehensive training programs, the risk of accidents and injuries is minimised. MAMS also aids in meeting regulatory requirements and industry standards related to equipment operation and maintenance, ensuring compliance and mitigating legal and operational risks.

Conclusion

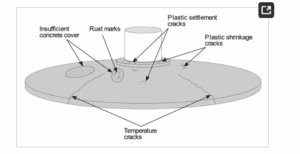

A well-implemented Machinery Asset Management Strategy (MAMS) is vital for effective management of heavy machinery within a plant. Alphatec Engineering, a trusted industry leader, specialises in heavy machinery foundation rehabilitation, offering valuable solutions to enhance machinery performance and prolong its lifespan.

With their expertise in foundation engineering and rehabilitation, Alphatec Engineering can assist organisations in addressing the structural integrity of machinery foundations. By conducting thorough assessments and utilising advanced techniques, they can identify and rectify any underlying issues that may impact machinery performance and reliability.